Are you going against the grain?

When sanding wood, everyone knows you sand with the grain. If you don’t, you’re going to make a right mess of things. Printing is no different to sanding. If you want the best result possible i.e. everything lining up, with a nice smooth finish and without any cracking or curling of the pages, then it’s imperative that the grain direction is right. The heavier the stock the more critical this becomes.

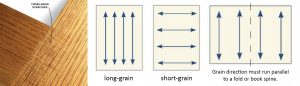

Grain! What grain? Yes, paper has grain. The grain of a sheet of paper is a result of the manufacturing process as the fibers line up in the same direction. A sheet of paper is either short grain or long grain and this is determined by which edge the grain runs parallel with. If it runs parallel to the long edge then it is referred to as long grain if it runs parallel to the short edge then it is referred to as short grain.

Cross-grain scratches from sanding against the grain is the equivalent to getting the grain direction in paper wrong when printing and folding.

The best grain direction when printing can vary based on what is being printed i.e. how many colours, and how it is being printed e.g. offset (lithography) or digital as these are very different processes – Offset printing uses inks and there is more moisture involved where as digital printing uses toners and heat, not to mention their feeding systems i.e rollers etc. are completely different. E.g. Xerox recommend that paper is fed into their machines with the grain direction running parallel to the feeding edge (The edge that enters the machine first). So, in the case of the Xerox machine if the short edge enters the machine first from the tray, then you want short grain stock.

Regardless of which way is best to feed a particular machine this is not where it ends. Getting the grain direction correct is critical when it comes to finishing as well. If what you are printing is going to be folded or maybe even bound in a book, the grain direction must run parallel to the folds and in the case of a book parallel to the spine. This includes every sheet within the book as well, not just the cover. If the grain direction is running perpendicular to the fold you will get cracking along the folded edge, books may not sit flat or open properly and some pages may even resist turning.

So what does all this mean? A printer should know whether short grain or long grain is best suited to their presses. This determines which way the artwork is set up so that when it comes time to trim, fold and/or bind the grain is running in the right direction.

TIP: Score (crease) along the fold line before folding, this will flatten the fibers and give you a better fold. An important step particularly with heavier stock.

What if I am printing something that isn’t folded or bound into a book, does grain direction really matter? Yes it does. For a good quality print, the paper must be fed into the press with the grain running in the right direction. In the case of offset printing this aids in the registration process.

I know what your thinking… But surely, in this case, it doesn’t matter which way the artwork is setup on the paper? Well to some it may not matter, but for me the answer is still, yes it does. Let me explain using business cards as an example. I like business cards to have a good quality feel about them, as well as looking great from a design perspective. A lot of that quality feel comes from how ridged a card feels. I don’t like cards that are flimsy, folding easily in my hand, it makes the card feel thin and screams poor quality. A business card should be long grain (remember long grain means the grain is running parallel to the long edge) as this will provide maximum rigidity for the stock used. If you had 2 cards printed on the same stock and one was set up so that when it was trimmed it was long grain and the other was set up so that when it was trimmed it was short grain, you would be telling me that the second card was printed on thinner stock. This however is just an illusion created by the grain direction causing the second card to feel flimsy compared to the first.

My Print Solutions out sources printing to some of the best printers in Australia and overseas. With between 20-30 offset & digital printers that we work with, we as much as anyone know that not all printers are created equal. Providing consistent quality print is our highest priority and that starts with knowing what a printer is great at. E.g. we have a couple of printers that for all intents and purposes are very similar and are both extremely good at what they do. But we are only interested in what they are great at. When printing 400gsm business cards, one of these printers guarantees the right grain direction where as the other does not because they want to fit more business cards on a sheet. No prizes for guessing that when we print 400gsm business cards we only use the printer that guarantees the correct grain direction.

This is our approach with everything we print. It is a two-fold process. First, it’s about providing the right print solution based on what you need and second, putting it into the right hands, the hands of a printer that is great at that particular printing process.